- Position:

- Batte Melt pump > technic >

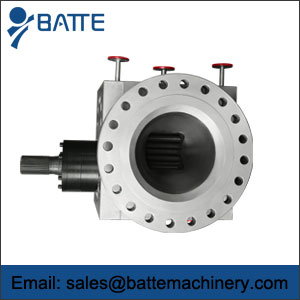

Industrial Gear Pumps

Industrial Gear Pumps include common gear pumps, internal gear pumps, Seal-less Internal Gear Pumps, Twin Screw, and Multi-phase Pumps. The industrial melt gear pumps technology is introduced as following details.Industrial Gear Pumps features a complete range of internal gear pumps and screw pumps, giving it the full capability to accommodate a wide range of applications. Internal gear pumps are ideally suited where a wide range of viscosities are prevalent and excel in higher viscosity applications.

Gear Pumps:

Gear Pumps displace fluid by the gears coming in and out of mesh, which draws the fluid into the pump and then forces the fluid through the discharge and downstream of the pump. The meshing actions of both the internal and external gear pumps are different by design. Internal gear pumps have a rotator and idler gear that come in and out of mesh, while external gear pumps have two coinciding gears that come in and out of mesh—this meshing is what creates the pumping action for both pumps. The overall area between each gear tooth ultimately determines the best-suited viscosity ranges for each type of gear pump.

Batte gear pumps for sale are critical in the precise and consistent transfer of highly demanding applications in the chemical and pharmaceutical industries, to name a few.

Seal-less Internal Gear Pumps:

Internal Gear Pumps feature a revolutionary seal-less design with patented between-the-bearing support system, effectively eliminating leaks and mechanical wear. These environmentally friendly positive displacement gear pumps have been designed to handle both thin fluids as well as hard-to-seal viscous fluids.

Screw Pumps:

Twin Screw Pumps are double-suction, self-priming twin screw pumps with external bearings and timing gears transmission. They are especially suitable for the delivery of fluids free of solid substances and/or with little abrasiveness. Twin Screw Pumps with non-timing gear transmission feature a single-suction design. The axial pressure on the hydraulic components is compensated by a balance piston. Metal contact exists between the screw profiles and casing bore. Twin Screw Pumps transfer lubricating fluids with higher viscosities, such as bitumen and residual oil, at medium or high temperatures.

Multi-phase Pumps:

Multi-phase Pumps are commonly used in oil fields with untreated streams. In order to satisfy the demands of oil, gas and water containing small particulates, the Multi-phase Pumps adopt a unique screw profile and design, along with a special pump casing chamber, to achieve an increase in mixture and heat distribution. A variety of materials and seals are available to meet challenging operating conditions in the field.

Other details about Industrial Gear Pumps please visit Batte website.

Relative Articles:

◆Discharge melt pumps

◆Prepolymer melt pumps

◆Thermoplastic Extrusion Melt Pumps

◆Precision melt gear pump

◆Chemical Pumps

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755