- Position:

- Batte Melt pump > technic >

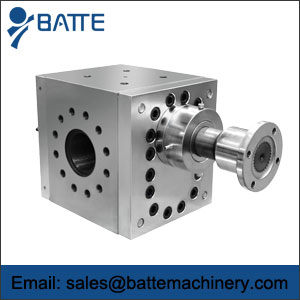

Thermoplastic Extrusion Melt Pumps

Thermoplastic Extrusion Melt Pumps can optimize the extrusion process of thermoplastics. These melt gear pumps are widely used in extrusion lines for their advantages of controlling pressure, modular construction, etc.

Thermoplastic Extrusion Melt Pumps Advantages:

Extrusion Gear Pumps optimize the extrusion process of thermoplastics since they ensure a constant flow of material, generate the required operating pressure and therefore relieve the extruder of pressure build-up.

This increases the production plant's performance, improves the quality of the end product, thanks to lower melting temperatures and extends the extruder's lifetime. Extruder pulsations and pressure peaks are also smoothed out or eliminated thanks to the extrusion melt pumps' attenuating effect.

Other advantages of thermoplastic extrusion melt pumps include the facts that waste products that occur internally can be reprocessed without problems and that the pump transports the melt through the moulding tool extremely evenly, ensuring a consistently high-quality end product.

The modular construction of thermoplastic extrusion melt pumps means that various needs and requirements can be addressed with ease. The advanced range features the characteristic quality features, superlative reliability and long service life of a extruder melt pump.

All thermoplastic extrusion melt pumps feature fully-optimised flow channel geometry, specially heat-treated shafts that can double the standing time as well as an innovative bearing design that allows higher speeds and therefore higher throughput rates. Wide ranges of viscosities and pressures are handled thanks to different clearances.

Relative Articles:

◆Melt pumps

◆Melt pump seal

◆Melt pump gear design

◆Prepolymer melt pumps

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755