- Position:

- Batte Melt pump > NEWS >

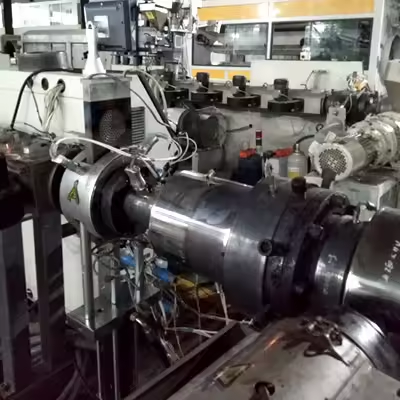

20~110mm PE Pipe Production Machine Line Plastic Pipe Making Machine melt gear pump

In the field of plastic pipeline manufacturing, the melt gear pump is one of the key equipment, and its performance and reliability directly affect the quality and production efficiency of the final product. This article will focus on introducing the plastic pipe making machine melt gear pump used in the 20-110mm PE pipe production line, analyzing its technical characteristics, working principle, and practical application in production, and exploring its role in improving the production efficiency and product quality of PE pipes.

Technical characteristics of melt gear pumps

As a special positive displacement conveying equipment, the melt gear pump has the following technical characteristics:

High precision measurement: The melt gear pump can achieve high-precision measurement of the melt through precise gear design and manufacturing, ensuring the uniformity and consistency of pipeline wall thickness.

Stable Transportation: The gear pump adopts a unique gear structure and rotation method, which can achieve stable transportation of melt under high viscosity and pressure, reducing fluctuations and faults in pipeline production process.

Low shear force: The flow of the melt in the gear pump is mainly driven by the rotation of the gear, and the shear force is relatively small, which helps to protect the molecular structure of the melt and reduce product quality loss.

Easy to maintain: The gear pump is designed with simplicity, easy disassembly and assembly, making it highly convenient for maintenance and cleaning.

The melt gear pump mainly consists of pump body, gear shaft, driving device, and temperature control system. During operation, two meshing gears rotate inside the pump body, and the melt is sucked in from the inlet and discharged from the outlet under the push of the gears. By adjusting the speed of the gears and the inlet and outlet pressure of the pump, precise control of the melt flow rate and pressure can be achieved.

The application of melt gear pump is crucial in the production line of 20-110mm PE pipes. It can not only ensure the stability of the melt during transportation, but also achieve precise control of pipeline wall thickness, thereby improving the overall quality of the pipeline. In addition, the high efficiency and long lifespan of the melt gear pump also contribute to improving the overall efficiency of the production line and reducing production costs.

In order to better understand the practical application effect of melt gear pumps in PE pipe production lines, we conducted a field investigation on a large plastic pipe production enterprise. The enterprise adopts advanced melt gear pump technology, and its PE pipe products have excellent performance in wall thickness uniformity, appearance quality, pressure resistance, and other aspects. By comparing the production data before and after using the melt gear pump, it was found that the production efficiency has increased by nearly 20%, and the product quality has also been significantly improved.

As a key equipment in the production line of 20-110mm PE pipes, the technical performance and application effect of the melt gear pump directly affect the quality and production efficiency of the product. With the continuous development of plastic pipeline manufacturing technology, melt gear pumps will also be continuously upgraded and improved to meet higher standards and more complex production needs. In the future, we look forward to the greater role of melt gear pumps in the field of plastic pipeline manufacturing, and to make greater contributions to enhancing the overall competitiveness of the plastic pipeline industry.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755