- Position:

- Batte Melt pump > NEWS >

What is the function of extrusion melt pump?

The polymer melt pump plays a crucial role in the plastic processing industry, with diverse and indispensable functions. As a key equipment, the melt pump is mainly used to control the flow and pressure of plastic melt, ensuring the stability and continuity of plastic during the extrusion process. The following will provide a detailed introduction to the functions of the extruder melt pump and its application in plastic processing.

Firstly, the extruder melt pump has precise flow control function. Stable flow rate is a key factor in ensuring product quality during plastic extrusion. The melt pump, through its unique design and working principle, can accurately control the flow rate of plastic melt, thereby ensuring the uniformity and consistency of plastic during the extrusion process. This precise flow control helps to reduce product defects, improve production efficiency, and lower production costs.

Secondly, the melt pump for extrusion also has excellent pressure control capabilities. During the plastic extrusion process, the melt pump can adjust the outlet pressure as needed to achieve precise control of the plastic melt. This pressure control ability helps to ensure the stability of plastics during the extrusion process and prevent product quality issues caused by pressure fluctuations. At the same time, the melt pump can also withstand high pressure, ensuring that the plastic does not leak or clog during the extrusion process.

In addition, the extruder melt pump also has the function of energy conservation and consumption reduction. The design of the melt pump is reasonable and can effectively reduce the energy consumption of plastics during the extrusion process. By increasing the temperature and pressure of plastic melt, the melt pump can reduce the frictional resistance of plastic during extrusion, thereby reducing energy consumption. This energy-saving and consumption reducing function not only helps to reduce production costs, but also improves the overall energy efficiency level of the plastic processing industry.

In addition to the above functions, the extruder melt pump also has the following advantages:

1. Efficient and Stable: The melt pump is manufactured using advanced control systems and high-quality materials, with efficient and stable working performance. It can operate continuously for a long time, maintain stable flow and pressure output, and ensure the continuity and stability of the plastic extrusion process.

2. Easy to maintain: The structure design of the melt pump is reasonable and easy to disassemble and clean. During maintenance, it is convenient to inspect and replace components such as the pump body and seals, thereby extending the service life of the melt pump. Meanwhile, the melt pump also has a lower failure rate, reducing maintenance costs and time.

3. Wide application range: The extruder melt pump is suitable for various types of plastic extruders, including single screw extruders, double screw extruders, plunger extruders, etc. Meanwhile, the melt pump can also be adjusted and optimized according to different plastic types and processing requirements to meet the needs of various extrusion scenarios.

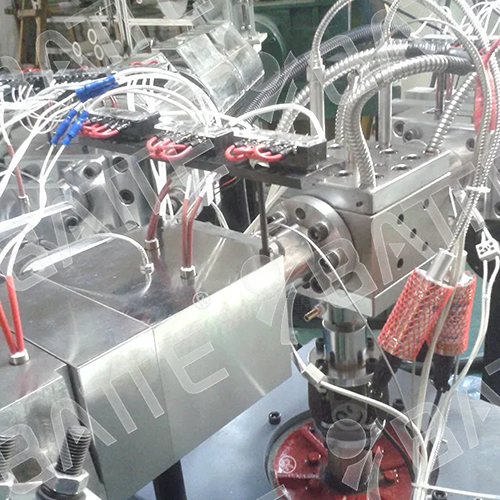

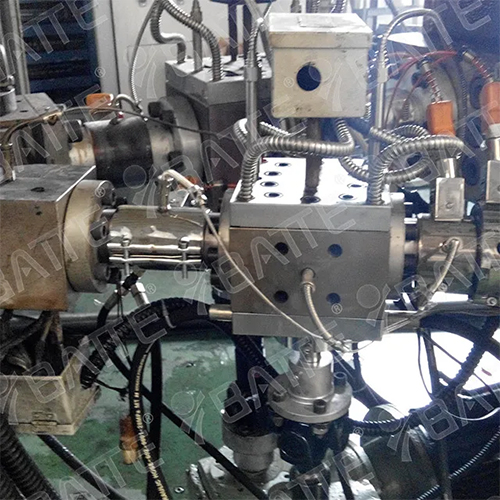

BATTE plastic melt pump for extrusion

In the plastic processing industry, extruder melt pumps are widely used in the production process of products such as pipes, sheets, films, wires and cables. Whether it is general plastics such as PVC, PE, PP, or special plastics such as engineering plastics and polymer materials, melt solution pumps can play their unique role in providing stable, efficient, and reliable solutions for the plastic processing industry.

In summary, as one of the important equipment in the plastic processing industry, the extruder melt pump has multiple functions such as precise flow control, excellent pressure control, energy conservation and consumption reduction. These functions enable the melt pump to play a crucial role in the plastic extrusion process, providing strong support for the development of the plastic processing industry. With the continuous progress of technology and the expansion of application fields, it is believed that the future extruder melt pump will have broader application prospects and richer functional characteristics.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755