- Position:

- Batte Melt pump > NEWS >

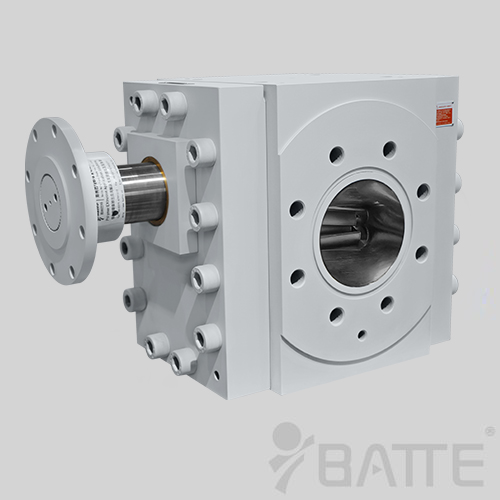

Gear lubrication pump temperature control

Temperature control melt gear pump is once again focusing on the needs, the use of ZenithPEP-II's role as a gear extruder back pressure drop will reduce polymer resides in the moment and make the machine more stable plasticizing process when extruder keep the velocity and pressure of a pump at the inlet of the gear pump extrusion system, smooth practice than the extrusion temperature of the extruder system at a temperature drop at the outlet of many. even if there is a rise in the pump, the overall temperature than the conventional extruder system is still lower.

Table clarity in a production process, in the low speed operation than the operation of a small displacement pump at high speed advantages exhibited by a large displacement pump. Seen from this figure, at a flow rate of 80 lbs / hr, three different displacement pump, the temperature results are as follows:

Displacement (cc / rev) speed (rpm) temperature (° C) 10 ~ 803020 ~ 401230 ~ 278

Based on specific heat and thermal conductivity, on the other polymers have similar results are calculated pump temperature:

T (° C) = 2Π × TV × N/16800 × Q × SH

During TV = viscous torque (lb-in) Q = Flow (1b/min)

N = pump speed (rpm) SH = specific heat

Show an example of the temperature rise. melt pump for extruder is used ZenithPEP-II, displacement 100cc/rev, showed a different speed and not under the same pressure temperature changes

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755