- Position:

- Batte Melt pump > NEWS >

Domestic best quality lowest price wholesale prices melt pump

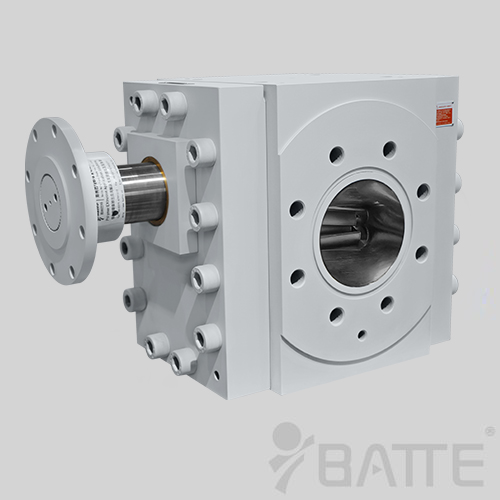

Domestic best quality lowest price melt pump wholesale price - Batte Zhengzhou Zhongyuan melt gear pump is well-known manufacturers of stainless steel gear pump, gear pump Batte introduction of German high-technology, research and production since its praise at home and abroad! Batte melt pumps are positive displacement gear pump, gear together outside using a cylindrical gears (spur, helical, herringbone teeth) relative rotation to transport to send high-viscosity fluids. All gear and mating surfaces are ground, and strictly control the assembly clearance to get accurate flow. Depending on the gear and pump a total situation, ZB-B series uses chrome-nickel alloy steel, tool steel, high-temperature materials; ZB-H series using imported CPM tool steel or titanium, tantalum alloy material, the overall quenching, hardness HRC62-68, wear-resistant good. Bad company has a complete laboratory, replicable processes of its customers, providing test results of the experiment before purchasing equipment for your reference. When the melt gear pump and a single-screw or twin-screw extruders in series, the whole production line can benefit significantly increased!

Domestic best quality lowest price melt pump wholesale price - Zhengzhou Batte melt pump Co. produces high viscosity pump before starting the operation, to the internal gear pump casing filled with the liquid to be transported for safe start. If the ambient temperature is below freezing, the pump should advance to pass into the hot steam, preheating before starting the gear pump. Direction of rotation to the high viscosity pump inlet and outlet ports consistent. Gear pumps if the first run, or long-term idle before use, the best start and under no-load or low load conditions Unity hours. If the running-in phase advance notice abnormal temperature, leakage, vibration and noise, you should stop to check.

Domestic best quality lowest price wholesale prices melt pump - Pump Co., Ltd., Zhengzhou Batte melt melt pump is a positive displacement delivery device, flow and pump speed was strictly proportional relationship. Mainly by the casing, the drive gear, the driven gear, sliding bearings, front and rear end plates, filling and sealing components. Tooth profile by the two gears, pump, pump side cover constitutes the feed zone, conveying zone and the discharge zone. Working volume changes depend working intermeshing driving and driven gears to convey melt caused. Working volume by the pump, and the gear splines with the side plates constituting the bearing function (i.e., the feed zone). When the gear is rotated in a predetermined direction, i.e., the melt feed into the alveolar region of the gears, with the gear, is brought into the melt from both sides of the conveying zone, the gear again to make the melt alveolar discharge region is extruded body discharge pressure to the outlet pipe. As long as the shaft rotates, the gear is sent to the outlet on the pressure side of the melt, and therefore can achieve high pump outlet pressure, flow and pressure of no import requirement is too high, even imported vacuum suction can be widely used in plastics, resin, rubber extrusion, such as granulation, film, pipe, sheet metal sheets, etc., can be divided according to the spur gear, helical, herringbone teeth and so on.

Domestic best quality lowest price melt pump wholesale price - Zhengzhou Batte Ltd. provides high-viscosity Melt Pump For Extruder.

A high viscosity pump Overview

NYP series of ordinary (stainless steel) inner-type high viscosity pump is based on the needs of the petroleum, chemical, paint, oil, pharmaceuticals, dyes, food and other industries, research and development of new positive displacement pump, because the product may use different materials and their unique structure, it is widely used in different properties of the medium transporting different viscosity.

High viscosity pump for medium temperature: -10 ℃ -200 ℃ (NYPO.78 and applicable temperature NYP2.3 is -10 ℃ -80 ℃).

High viscosity pump for medium viscosity: 1.0cSt-300, 000cSt (NYPO.78 and viscosity NYP2.3 applicable for 1.0cSt-10, 000cSt).

Second, the advantage of a high viscosity pump

(1) smooth transportation of liquid, no pulsation, vibration, low noise.

(2) have a strong self-absorption properties.

(3) the correct selection of parts and materials, can transport a variety of corrosive media, temperature can be 200 ℃.

(4) the same inside and outside of the rotor turning, small abrasion, long service life.

(5) the pump speed and flow rate was a linear function, can also be appropriately changed to change the transfer pump flow.

(6) especially suitable for transporting highly viscous consistency of the medium.

Domestic best quality lowest price wholesale price ---- melt pump for extrusion melt gear pump company in Zhengzhou Batte cheap, welcome new and old customers to negotiate consulting!

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755