- Position:

- Batte Melt pump > NEWS >

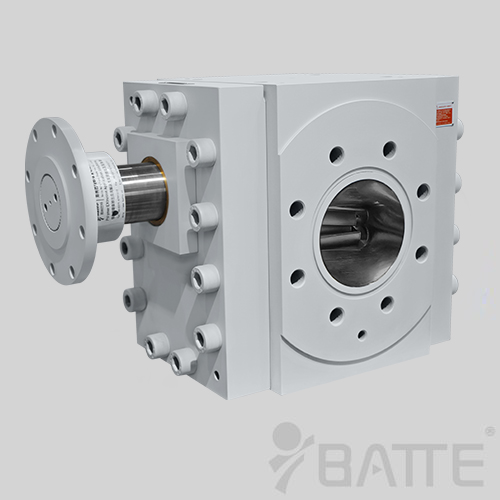

Loaders melt pump seal channeling oil Phenomenon

"Melt pump channeling oil" that hydraulic oil to oil seal breakdown and overflow. This phenomenon is widespread, reflecting the strong OEM, melt pump channeling oil seriously affect the normal work and melt pump loaders reliability and environmental pollution.

If oil seal lip geometry failed, tightening the spring is too loose, resulting in leak tightness testing, melt pump after loading the host channeling oil. You should replace the seals and test the material and geometry (domestic and foreign advanced seal seals the gap compared to the larger mass).

Should the melt pump processing, assembly problems, resulting in the gear shaft rotation center and the front cover only the mouth misalignment will cause the seal eccentric wear. At this point the front cover bearing bore should be checked against the pin hole symmetry, displacement, oil seal for the bearing bore concentricity.

If you have this problem, resulting in cracks and scratches sealing ring, causing secondary Mifengbuyan even failure, the pressure of the oil into the oil seal (low channel), thus channeling oil seal. You should check the seal ring material and processing quality.

Get feedback from OEMs, assembled together with the variable speed pump melt pump seal channeling oil problem is more serious, so the quality of the processing speed of the pump also has a greater impact on channeling oil. Variable speed pump mounted on the gearbox output shaft, a melt pump and gear pump through the Mouth positioning installed in the gearbox output shaft, variable speed pump only if the port side face runout tolerance (verticality) gear rotation center, and also make the gear shaft rotation center does not coincide with the center seal affect seal. Variable speed pump processing, the trial process, you should check the rotation center of the coaxial port and ending on the end face of the Mouth of beating.

Before the melt pump oil seal between the lid and the seal ring oil return passage is not blocked, causing pressure rise here, so the breakdown oil seal. Through the improvement of here, the phenomenon of channeling oil pump has been significantly improved.

Usually working pump installed in the variable speed pumps, variable speed pumps were installed in the gearbox. If the end face of the gearbox or variable speed pump rotation center spline shaft runout tolerance, forming the accumulated error, resulting in a melt pump radial force at high speed rotation state, resulting in channeling oil seals.

Melt pump with variable speed pump outside the mouth of the Mouth and the melt pump and gearbox external spline shaft spline spend the key, with the gap between the two is reasonable, melt pumps are channeling oil influential. Because inside, outside the mouth belongs to locate part, with the gap should not be too big; internal and external splines are transmission parts, with the gap should not be too small, in order to eliminate interference.

As the melt pump for extrusion shaft splines and extended the gearbox output shaft spline effective contact length is short, and the work of the melt pump torque transmitted is larger, its spline withstand high torque and wear occurs even squeeze roll keys, produce giant heat, resulting skeleton rubber lip seal burns, aging, and thus appear channeling oil. Melt pump should be chosen mainly recommend checking melt strength spline shaft overhang, to ensure adequate and effective contact length.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755