- Position:

- Batte Melt pump > NEWS >

Around the gear pump using features

Over the years, I plant to produce gear pumps became famous for spending below our operating companies to introduce the use of a gear pump characteristics:

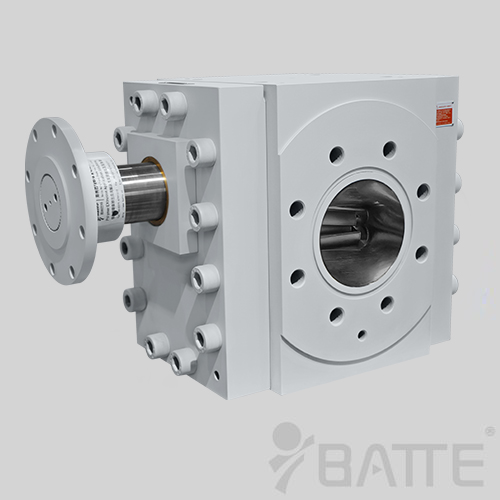

Arc gear pump relies on the operating volume change and move between the pump cylinder and gear formed so as to transport liquids or pressurized reverse pump. External mesh double gear pump layout. A pair of gears meshing with each other and the pump cylinder chamber and the discharge chamber from the suction compartment. The rolling gear, the suction chamber side of the teeth of the teeth disengage from each other and gradually increase the volume of the pressure drops, the liquid under pressure into the interdental effect. Followed by rolling gear teeth of one liquid is brought to the discharge chamber. Then the teeth meshing at the discharge chamber side volume gradually decreases and the liquid discharge. Gear pumps are suitable for transporting solid particles, non-corrosive, larger lubricating viscosity liquids.

Arc gear pump layout simple and compact, making simple, easy to protect, there are self-priming ability, but the flow, pressure pulsation large and noisy. Gear pumps are equipped with the necessary safety valve to prevent the discharge pipe for some reason, such as blocking the outlet pressure of the pump beyond the permissible value of damage to the pump or prime mover gear to adopt new technologies with the world's advanced level of ninety people - double round tooth circular arc sine curve. It compares with involute gear, the most prominent advantage is the process of gear tooth profile surface without sliding, so no tooth wear, operating balance, no trapped fluid appearance, low noise, long life, high efficiency. The pump is bundled with traditional planning to get rid of the gear pump in the planning, production and use of advances into a new category.

Gear pump type Meaning: to 2CY7.5/2.5 to explain, 2CY that double gear; 7.5 cubic meters / hour, 2.5MPA (pressure). Pump gears, shafts, pump, pump cover, sleeve bearings, shaft seals, etc., and gear after nitrogen treatment had a higher hardness and wear resistance; together with the shaft device replaceable bushings in the job, all parts of the pump lubrication pump operations are used when transporting medium and active reach; within four bearings of the pump in the pump sets from the floating device, with the initiative to adjust the size of the operating pressure of the end face of the gap, so the pump pressure is stable, the output flow pulsation Small, high melting volumetric efficiency.

Welcome new and old brother to call us pick our gear pump communication and collaboration, win-win situation unfold.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755