- Position:

- Batte Melt pump > NEWS >

Batte participate in 28th International Rubber Exhibition rewarding

2014 4.23 days, twenty-eighth China ( Shanghai ) International Plastics and Rubber Industry Exhibition in China Shanghai New International Expo Center grand opening ! Melt Pump Co., Ltd., Zhengzhou Batte on CHINAPLAS 2014 Chinaplas successfully carried out. Batte 's booth number is W2P51, located in the central exhibition of the most prominent position !

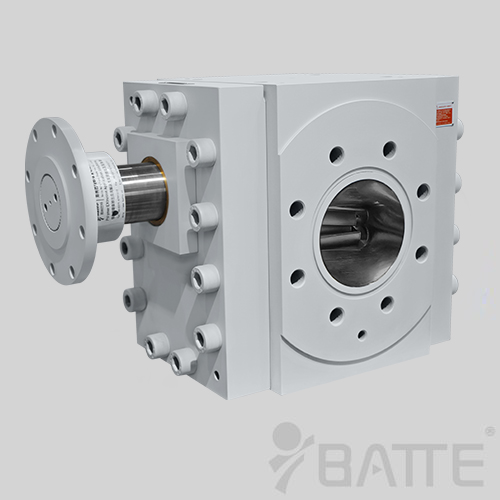

The exhibition, Batte brings not only has the world's cutting-edge technology ZB various series of melt pumps, metering pumps, melt gear pump, and FB series melt metering pump, also brought melt pump application extruder production line, allowing customers and friends at a glance, are more familiar with the advantages and Batte melt pump excels !

On the show, more than 3,000 exhibitors from around the world to participate in this event and showcase the world's rubber cutting edge of technology. From 23 to Saturday, is expected to have 120,000 visitors see a rich variety of exhibits rubber machinery, equipment, chemicals and raw materials at the show. Whether it is the latest cutting-edge technology, or cost-effective products, CHINAPLAS Chinaplas are committed to meet the expectations of the audience.

Under the " Green Plastic Innovation ● Build eternal" theme, CHINAPLAS 2014 is being organized by the exhibition site of two concurrent events : "Future City" show and "green forum." "Future City" is located in the central square of Expo Center, which is in a circular display area, showing the sustainable development of plastics and rubber products ; " Green Forum " is a term of two half-day meeting of the two themes, entitled " plastic recycling innovative solutions "and" green molding - half the cost, profit doubled. "

Supplementary melt pump Tidbits:

The main function is to pump the melt temperature of the plastic melt from the extruder pressurized flow steadily into the extrusion head regulator. Its steady melt pressure and flow capacity than types of extruders. When it with a single-screw or twin-screw extruder used in tandem, it makes the whole production line efficiency is significantly increased. The main advantage of using a melt pump are:

1. The extrusion products to minimize dimensional tolerances, material per unit weight of the system out more products. In extrusion products require strict dimensional tolerances or products more expensive raw material costs, the use of a melt pump for extruder more necessary, more valuable.

2. The co-rotating twin -screw extruder and melt pump synthetic compounding extrusion granulation production line, its mixing quality and yield significantly higher than single twin-screw granulation unit. Energy consumption per kilogram of processed material can generally be reduced by about 25 percent.

3. In the original single -screw or twin-screw extruder granulator melt pump and the installation of tubes, plates, film extrusion head, the granulation step can be omitted direct extrusion products. This system is ideally suited for extrusion products need to go through the material blend modified occasion. In addition the system has the advantage of the first two, but also by simplifying the production process of extrusion products, shortening the production cycle to achieve energy savings.

4. can be achieved using more than one medium and small extruder simultaneously to a melt pump

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755