- Position:

- Batte Melt pump > FAQ >

Safety Protection Measures of Melt Booster Pump

1. Improving the Reliability of Melt Pressure Detection by Redundancy Method

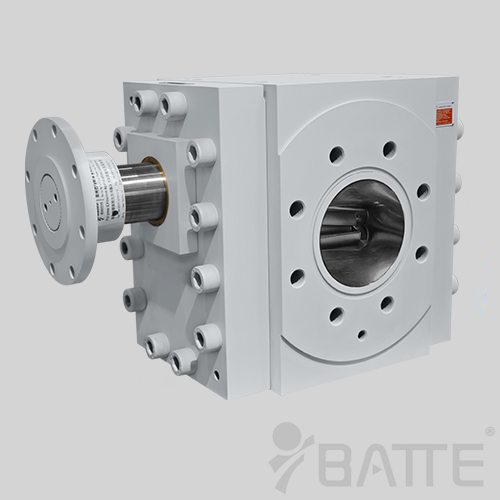

Because of the high power of the melt booster pump, the high temperature and pressure of the transported polyester melt, the measurement of the outlet pressure of the melt booster pump is required to be reliable and accurate, and safety accidents due to the failure of the pressure gauge are not allowed. Using the redundancy method, two pressure transmitters are installed at the outlet of the melt booster pump to measure the pressure (as shown in Figure 3). Then a higher pressure transmitter is selected by the selection module to calculate the deviation value, so as to ensure the reliability and accuracy of the pressure measurement, reduce the chance of failure and improve the reliability of the system.

2. Safety interlock protection of melt booster pump before start-up

Before starting the melt booster pump, it is necessary to ensure the smooth outlet of the booster pump, otherwise the consequences will be unimaginable. As shown in Fig. 4, the switching condition of each valve is measured and judged. The signal processed by logic is connected into the starting control circuit of the converter to decide whether to allow the starting of the converter to ensure that at least one pipeline is open at the outlet of the booster pump before starting the booster pump.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755