- Position:

- Batte Melt pump > technic >

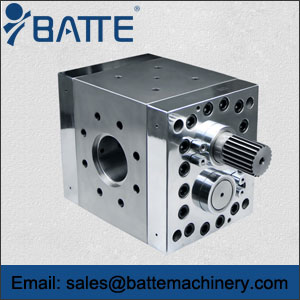

Gear pumps for rubber application

Gear pumps for rubber application are high precision gear pump for metering and pressure generation tasks. Rubber gear pumps provide a reliable means to increase capacity of existing lines.

Gear pumps for rubber applications:

Melt gear pumps provide a reliable means to increase capacity of existing lines, improve the dimensional stability of extruded profiles, efficiently build high pressure required for strainer applications and provide an excellent return on investment. The benefits of gear pump assisted extrusion are well known for thermoplastic applications and many of the same benefits can be realized for rubber. The key to a successful rubber pump installation is the correct pump design and pump size selection. Batte’s ability to provide proven solutions for the rubber industry and our strength in providing an engineered solution to our customer’s unique requirements gives our customers an advantage.

Gear pumps for rubber materials:

Housing: Alloy steel with stainless steel options

Gears: Through hardened and nitrided H13 tool steel

Friction Bearings: Through hardened D2 tool steel; optional: other materials

Shaft Seal: Viscoseal; optional: other materials

Heating/cooling: Jacketed pump housing and tempered gearshafts for use with pressurized hot water temperature system

Gear pumps for rubber application are mainly for EPDM, CR, NR, NBR, SBR, NR FPM, BR and other rubber materials. We adopt the best materials for housing, gears, friction bearings, shaft seal, and other parts of melt gear pumps.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755