- Position:

- Batte Melt pump > NEWS >

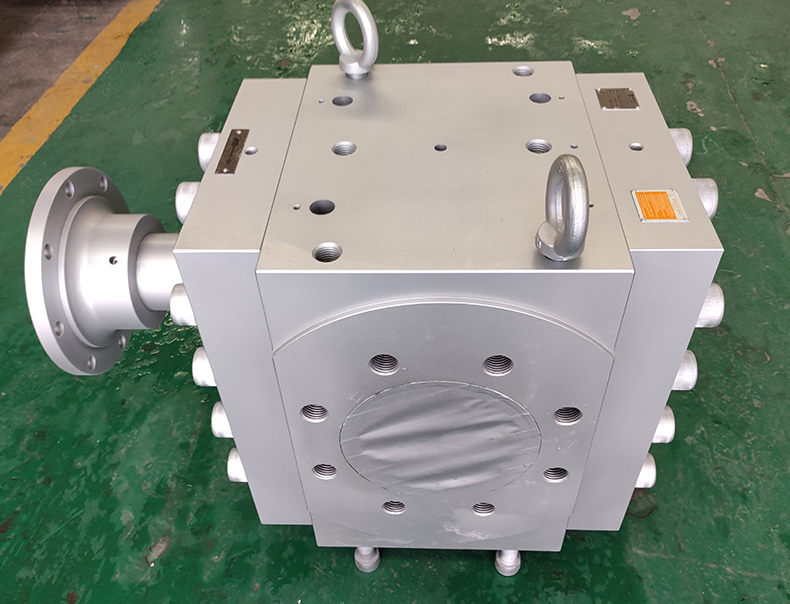

Precision Extrusion Melt Gear Pump for PVC

In the field of plastics processing, polyvinyl chloride (PVC) is widely used in the large-scale production of various products such as pipes, sheets, films, and profiles due to its excellent mechanical properties, corrosion resistance, and cost advantages. However, PVC's inherent heat-sensitive nature creates an extremely narrow processing window. It exhibits high sensitivity to temperature fluctuations during processing, making it prone to decomposition and carbonization due to localized overheating. This can lead to charring defects, severely compromising the final product's appearance and performance while disrupting production line continuity and causing significant economic losses. Addressing this core industry challenge in PVC processing, Zhengzhou Batte leverages its deep technical expertise in analyzing PVC material properties to develop highly specialized PVC melt gear pumps. These pumps provide comprehensive technical support for precision PVC extrusion.

I. Core Technical Challenges in PVC Material Processing

As a typical non-crystalline, heat-sensitive polymer, PVC's processing difficulties primarily center on three aspects that directly constrain extrusion process stability and product precision:

Extremely Poor Thermal Stability: During processing, prolonged exposure to high temperatures or sustained heating causes PVC to readily undergo hydrochloric acid (HCl) degradation. This triggers molecular chain breakage and material discoloration, ultimately leading to significant deterioration in mechanical properties and loss of functional value.

High melt viscosity and sensitivity to shear stress: PVC melt exhibits inherently high viscosity and pronounced sensitivity to shear rate and shear stress. Processing requires precise balancing of temperature and shear force parameters. Improper parameter matching readily causes melt fracture and material degradation, compromising extrusion stability.

Stringent Process Control Precision Requirements: During PVC extrusion, even minor temperature fluctuations or pressure pulsations are amplified, directly causing unstable melt outlet flow. This ultimately results in defects such as uneven sheet thickness, pipe roundness deviations, and surface scratches on profiles. Traditional processing methods, relying solely on screw extruders for pressure build-up and material conveyance, inevitably produce significant temperature and pressure pulsations, making it difficult to meet the precise extrusion requirements for PVC.

II. Core Solution: PVC-Specific Melt Gear Pump

Zhengzhou Batte, addressing the heat-sensitive and high-viscosity characteristics of PVC materials and leveraging years of extrusion equipment R&D experience, has introduced a PVC-specific melt gear pump. Its core solution lies in separating the “pressure build-up” and “metering” functions from the screw extruder through positive displacement conveying principles. This achieves precise control and revolutionary optimization of PVC melt conveying, fundamentally resolving the pain points of traditional processing. This PVC-specific melt gear pump features a comprehensive adaptive structural design centered on material processing characteristics, with the following core advantages:

Optimized flow channel and gear structure: The pump inlet features a funnel-shaped streamlined flow channel design, ensuring PVC melt enters the gear meshing zone smoothly and stably. This minimizes melt residence time and shear-induced heat generation within the flow channel, preventing material degradation and carbonization caused by flow dead zones. Simultaneously, precise optimization of internal flow channel dimensions and gear parameters achieves low pressure loss and high uniformity during melt conveyance, further enhancing extrusion stability.

Built-in Melt Self-Lubrication System: Utilizing a unique integrated lubrication channel design, the system employs the PVC melt itself as the lubricant. A small volume of melt continuously lubricates critical moving components such as gears and bushings. The lubricated melt then flows into downstream forming equipment alongside the main material, eliminating the need for an external oil injection system. This design not only simplifies equipment structure and reduces maintenance costs but fundamentally eliminates contamination of PVC material by external lubricants. It is particularly suitable for PVC product manufacturing scenarios with high material cleanliness requirements, such as medical and food packaging applications.

High-Precision Gear Clearance and Positive Displacement Structure: Through precision machining that strictly controls gear meshing clearance, combined with a volumetric cavity design, the melt gear pump achieves precise metering and stable control of PVC melt delivery. This effectively eliminates extrusion instability caused by factors like uneven upstream feeding, temperature fluctuations, and screw speed variations, ensuring constant melt outlet flow. Ultimately, it enables high-precision, uniform production of PVC products.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755