- Position:

- Batte Melt pump > NEWS >

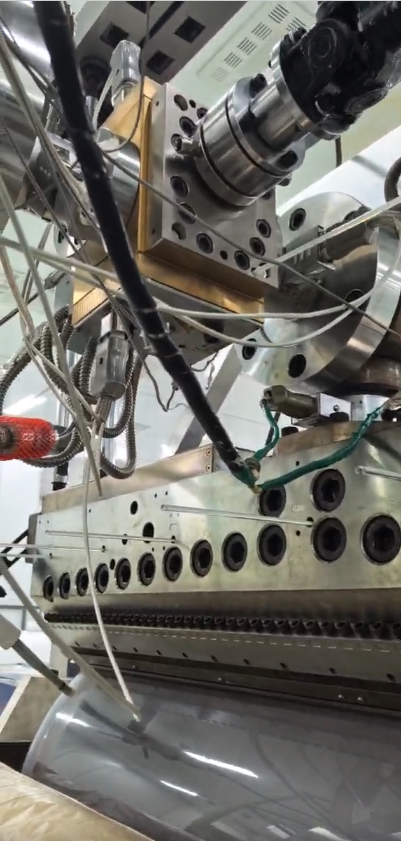

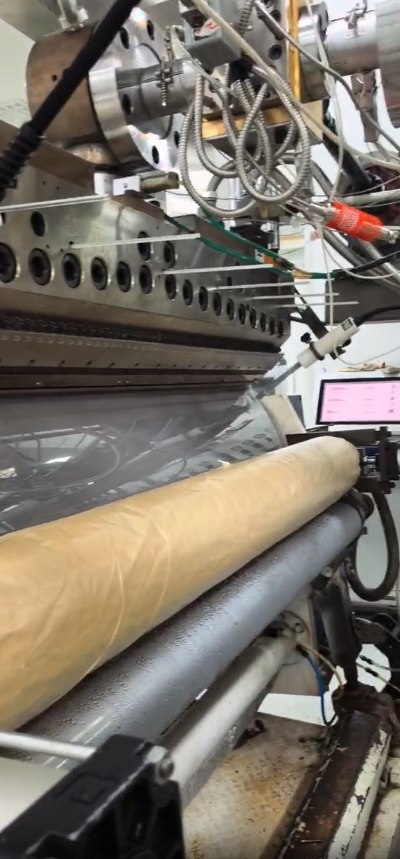

Melt pumps for ETFE agricultural greenhouse film extrusion lines

The central role of melt pumps in ETFE film extrusion

ETFE (ethylene tetrafluoroethylene copolymer) films are widely used as agricultural greenhouse covering materials due to their weather resistance, light transmission (up to 90% or more) and self-cleaning properties. In the extrusion line, the melt pump, as the key power equipment, mainly assumes the following functions:

Stable conveying and pressurization

ETFE melt has high viscosity (viscosity range 1~40,000Pa-s), melt pump forms stable working volume through gear meshing to pressurize and convey high temperature melt from the extruder to the die head, ensuring stable outlet pressure (output pressure 0~40MPa), avoiding uneven thickness of film due to pressure fluctuation.

Precise Flow Metering

The flow rate of the melt pump is strictly proportional to the rotational speed. Combined with the optimized melt flow channel design (eliminating the dead space of the flow channel), the melt flow rate can be linearly controlled, which meets the stringent requirements of agricultural greenhouse films for uniformity of thickness (within ±1%).

Process optimization and energy saving

Low-temperature extrusion: The melt pump transfers the extruder's decompression function to the pump body, allowing the extruder to operate at low pressure and low temperature (operating temperature ≤350°C), reducing the risk of thermal degradation and prolonging equipment life.

Reduced energy consumption: By stabilizing the melt pressure and reducing leakage, the energy consumption per kilogram of material processed can be reduced by about 25%, which is in line with the demand for cost reduction in the mass production of agricultural greenhouse films.

Typical configuration of a melt pump in an ETFE film extrusion line

Components

Core components: pump casing (stainless steel/corrosion resistant alloys), helical or straight toothed cylindrical gears (nitrided steel/stainless steel + coating), plain bearings (copper alloys/stainless steel + coating), packing seals or mechanical seals.

Auxiliary system: electric heating or thermal fluid runner heating (to ensure melt temperature uniformity), PLC touch screen control (to realize real-time pressure/flow monitoring and feedback adjustment).

Key parameters

Conveying medium viscosity: 1~40000Pa-s (covering the range of ETFE melt viscosity).

Suction pressure: 0-30MPa; output pressure: 0-40MPa.

Permissible differential pressure: 25MPa (to adapt to high resistance extrusion conditions).

Output range: 350-500kg/h (single-screw extruder with pump).

Application Scenario

Agricultural greenhouse film: Through the combination of melt pump and casting machine, it realizes the precise control of film thickness from 0.1 to 0.5mm, and meets the light and heat preservation requirements of permanent buildings (more than 25 years' life).

Photovoltaic film: some production lines (e.g. GW brand) steadily deliver ETFE melt through melt pumps for solar cell encapsulation film production, with a loss of light transmittance of <2%.

Selection recommendations

Viscosity matching: according to the ETFE melt viscosity (usually 10,000 to 30,000 Pa-s) to choose the gear type (helical gear is more suitable for high viscosity conditions).

Temperature control: Priority should be given to the use of thermal fluid channel heating pump body to ensure that the melt temperature fluctuations <±2 ℃.

Seal structure: recommend mechanical seal or dynamic seal with cooling melt under high temperature working condition to prevent leakage.

Automation requirements: if you need to link with the casting machine, winding system, choose the melt pump model that supports PLC control.

In ETFE agricultural greenhouse film extrusion lines, melt pumps significantly improve the dimensional accuracy, surface quality and production efficiency of the film through stable conveying, precise metering and process optimization. Combined with industry cases, we recommend melt pumps with corrosion-resistant alloy bodies, helical gears and mechanical seals, and prioritize PLC control systems to meet the stringent requirements of high-end agricultural greenhouse films.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755