- Position:

- Batte Melt pump > NEWS >

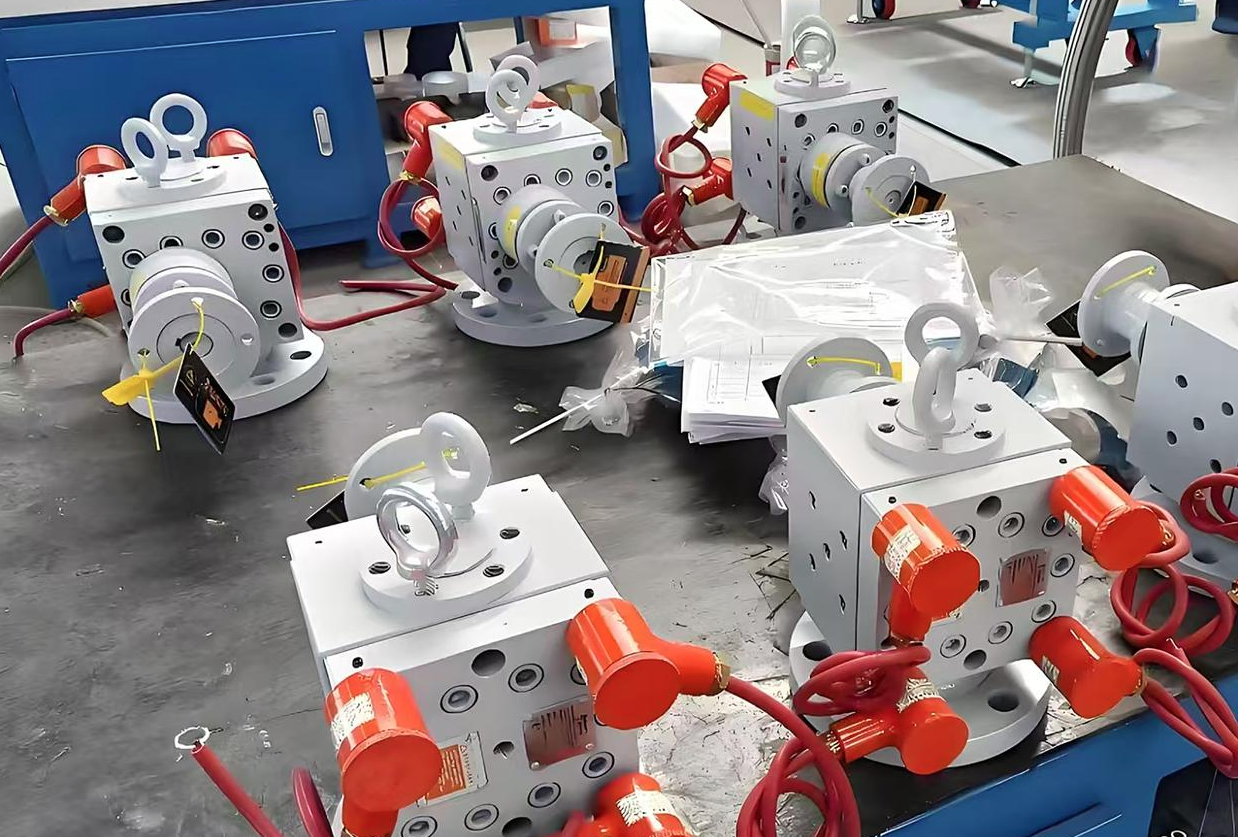

Do you know about melt pipeline booster pumps?

Melt pipeline booster pumps are special industrial pumps designed for high-viscosity melt transportation systems. They are mainly used in polymer processing, chemical fiber spinning, plastic extrusion, and other fields. Their core function is to overcome the flow resistance of melts in pipelines through mechanical boosting, ensuring stable transportation of melts under high-temperature and high-pressure conditions. Based on structural differences, they can be categorized into three main types: gear pumps, screw pumps, and piston pumps. Among these, gear pumps are the mainstream choice due to their compact structure and high efficiency. These pumps must withstand high temperatures of 200–400°C and high pressures of 10–50 MPa. Materials typically include tool steel or high-temperature alloys, and they are equipped with specialized sealing systems to prevent melt leakage.

Fluid dynamics principles of operation

Melt pressure pumps operate based on the positive displacement principle, achieving melt transportation through periodic volume changes in a sealed chamber:

-Intake stage: When the active rotor (such as a gear or screw) rotates, the meshing teeth separate to form a negative pressure chamber, drawing melt into the inlet;

-Compression stage: As the rotor continues to rotate, the melt is enclosed between the teeth and moved toward the outlet end through meshing motion;

-Discharge stage: The reduction in cavity volume creates a pressurization effect, and the melt is discharged from the outlet at a constant pressure.

Melt pipeline pressure pumps achieve high-precision metering and stable transportation of molten materials through the sealed cavities created by gear meshing. In the field of engineering plastic modification, when processing glass-fiber-reinforced plastics with a filler content exceeding 40%, traditional screw extruders are prone to melt fracture. However, the melt pump, when combined with a forced feeding system, can stably convey melts with viscosities exceeding 10,000 Pa·s, preventing excessive shear fracture of the reinforcing fibers. For example, after adopting this solution, a certain automotive parts manufacturer saw a 15% increase in tensile strength of the finished products and a 20% reduction in material loss.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755