- Position:

- Batte Melt pump > NEWS >

Silicone extruder melt pump application range

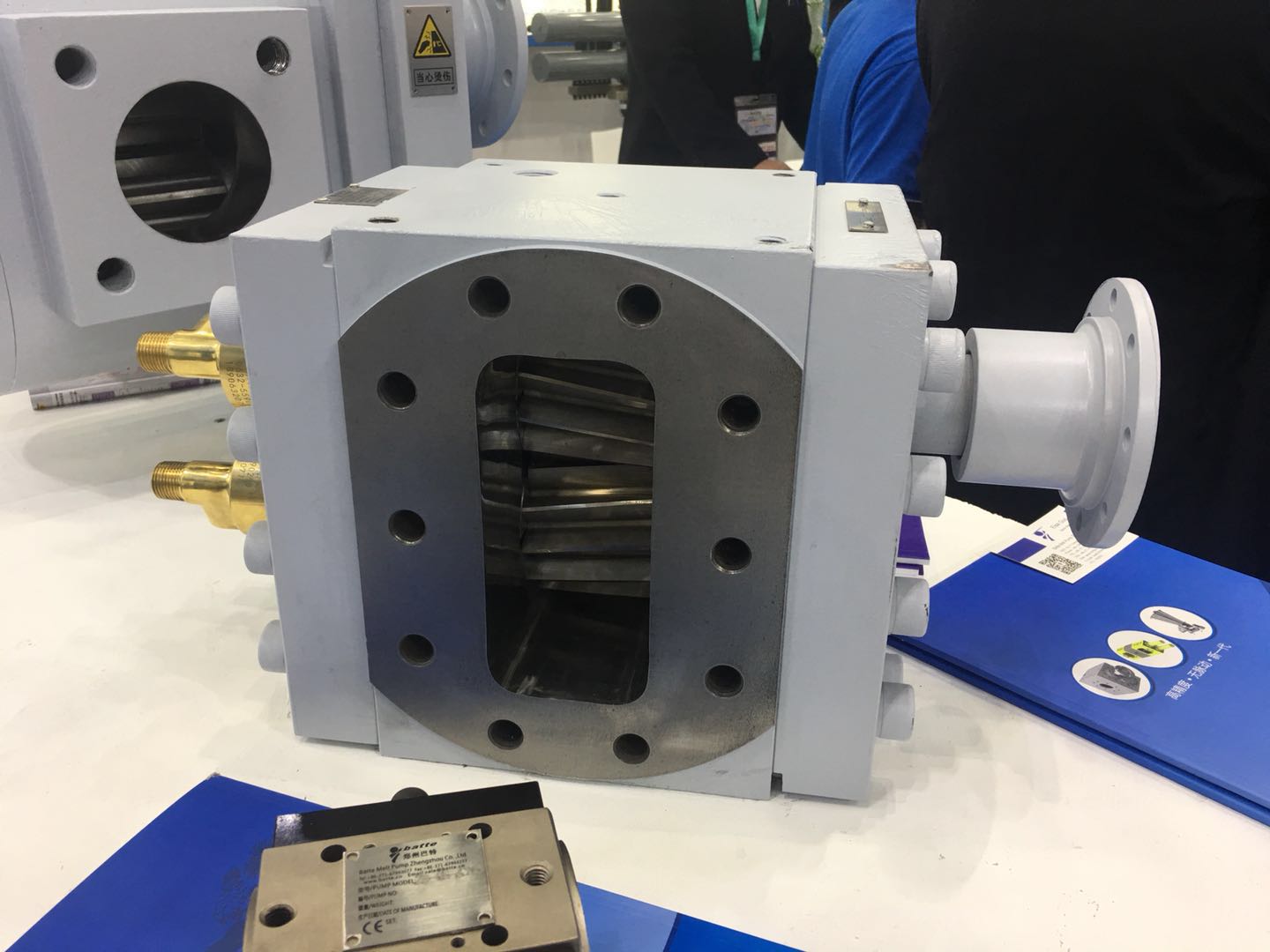

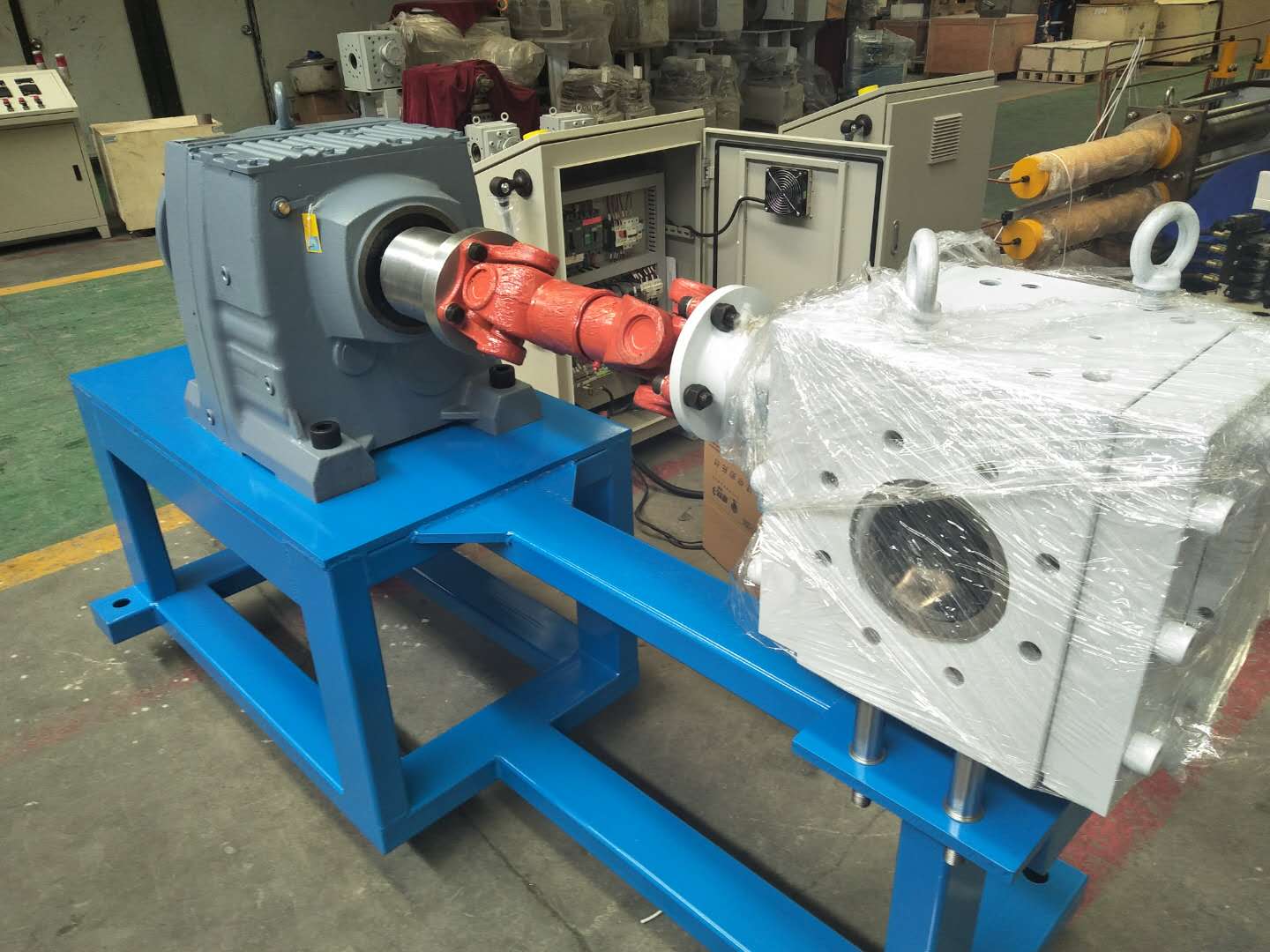

Silicone extruder melt gear pump is a key equipment specialized in silicone extrusion molding process, which has a wide range of applications and plays an important role in many industries. The following are the main applications of silicone extruder melt pumps:

Silicone Tubing and Profile Extrusion

In the production of silicone tubing (e.g., medical catheters, food-grade hoses) and profiles (e.g., sealing strips, cable sheaths), the melt pump ensures dimensional accuracy and wall thickness uniformity of the product through precise control of pressure and flow, which is especially suitable for stable extrusion of high-viscosity silicone materials.

Silicone Film and Sheet Production

For the production of optical-grade silicone films (e.g., display protection films) or functional sheets (e.g., thermally conductive silicone mats), melt pumps eliminate pressure fluctuations during extrusion and significantly improve film thickness uniformity and surface finish to meet precision processing requirements.

Silicone Seals and O-Rings

In the production of silicone seals for the automotive and electronics industries, melt pumps ensure dimensional consistency and physical properties of the seals by stabilizing melt delivery, reducing scrap rates, especially for simultaneous injection molding in multi-cavity molds.

Extrusion of medical-grade silicone products

For medical catheters, silicone balloons and other products with high cleanliness requirements, melt pumps, together with clean room design, can realize low-shear, non-polluting extrusion process and ensure that the products comply with ISO 10993 biocompatibility standards.For medical catheters, silicone balloons and other products with high cleanliness requirements, melt pumps, together with clean room design, can realize low-shear, non-polluting extrusion process and ensure that the products comply with ISO 10993 biocompatibility standards.

Silicone parts for electronics and electrical appliances

In 5G communications, new energy vehicles and other fields, used in the production of silicone thermal pads, insulating sleeves and other parts, melt pumps through accurate metering function, to ensure the dielectric properties and thermal stability of the product, to meet the stringent requirements of microelectronic devices.

Co-extrusion of silicone composites

In the production of multi-layer composite silicone materials (e.g. silicone/Fluoroelastomer composite tubing), melt pumps enable precise proportioning and synchronized extrusion of the different material layers to ensure the bonding strength of the layers and the stability of the overall performance.

Laboratory and small batch customized production

The modular design of the melt pumps supports quick changeover and is suitable for R&D testing of new silicone materials or small batch production of high-end customized products, with flexible adjustment of process parameters to suit different formulation systems.

Continuous Silicone Foaming Extrusion

In the production of silicone sponges, vibration damping pads and other foam products, the melt pump controls the foaming multiplicity and the uniformity of the pore structure by stabilizing the delivery of the mixture of blowing agent and silicone matrix to enhance the physical properties of the products.

The core value of the silicone extruder melt pump lies in its pressure stability (fluctuation <±1%), flow accuracy (repeatability ±0.5%) and material adaptability (can handle silicone with viscosity range of 10³-10⁶ Pa-s). By combining with single screw/twin-screw extruders, it can significantly improve production efficiency (capacity increase of 20%-50%) and product quality (pass rate increase to over 99%), especially in the field of high-end silicone products with irreplaceable.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755