- Position:

- Batte Melt pump > NEWS >

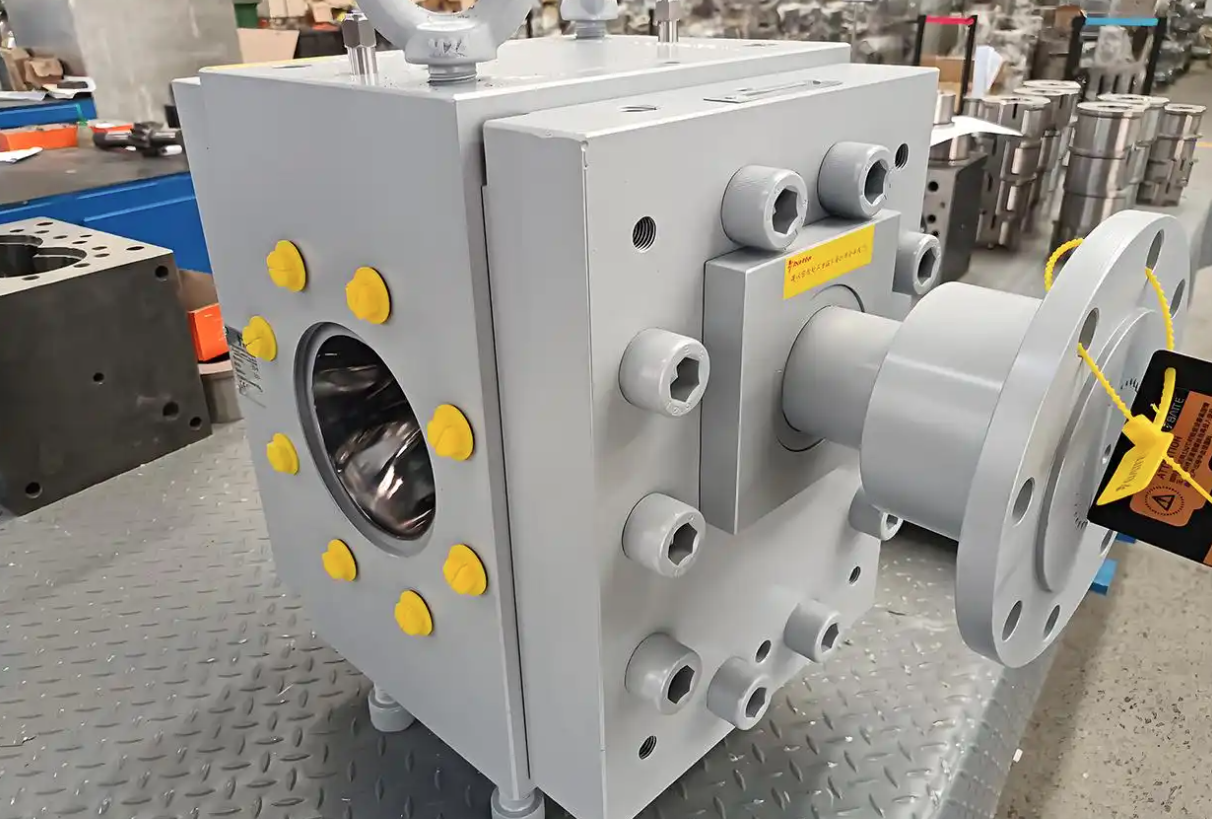

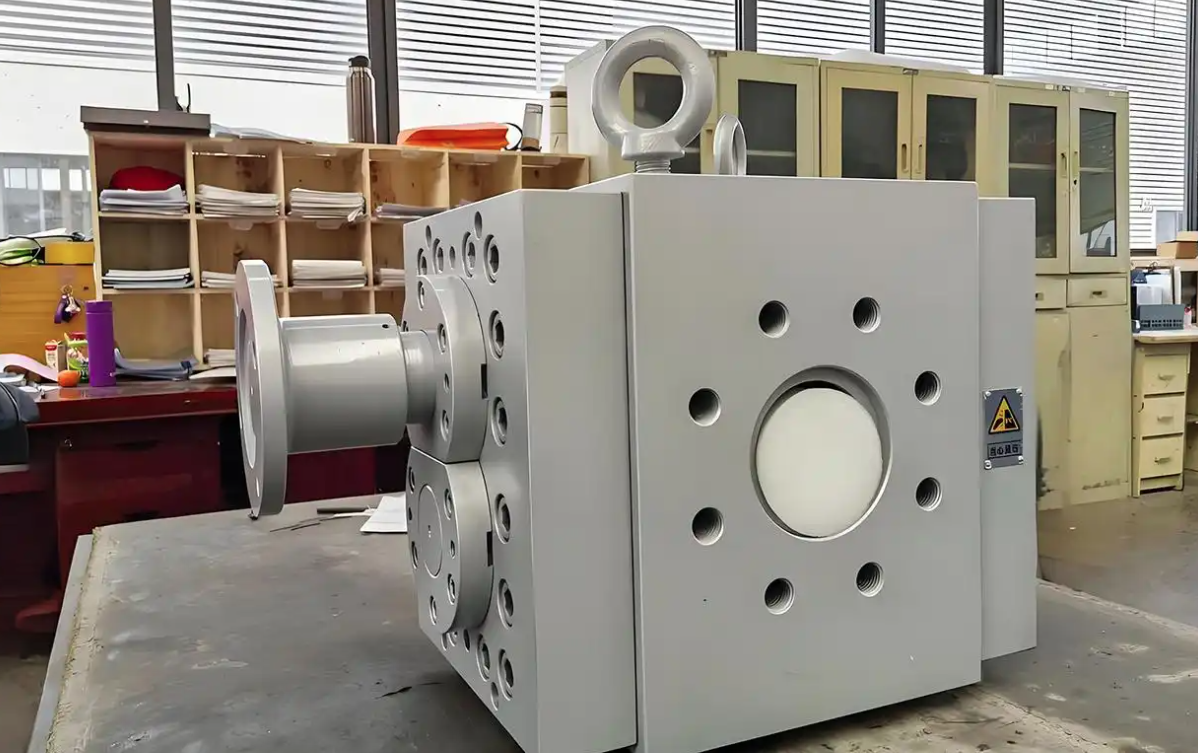

Specific applications of melt pumps in silicone extrusion

Stabilizing the flow and pressure of silicone melt is the basis of high quality production; high temperature and wear-resistant material casting equipment lasting and reliable, melt pumps with precise control and efficient sharing, enhance the uniformity of extrusion, reduce the failure rate, and become an indispensable core of the silicone products production line.

Stabilizing melt flow and pressure: The melt pump can stabilize and accurately control the flow and pressure of the silicone melt to ensure the stability and continuity of the extrusion process, which is the basis for the high-quality production of silicone products.

Improve melt homogeneity: The melt pump, through its unique pumping mechanism, helps to homogenize the melt and reduce air bubbles and impurities in the melt, thus improving the homogeneity and transparency of silicone products.

Reduced extruder load: The melt pump shares the working pressure of the extruder, enabling the extruder to run more efficiently, reducing wear and tear and prolonging the service life of the equipment.

Adapt to harsh conditions: the melt pump is made of high-temperature resistant, wear-resistant and corrosion-resistant materials, which can work continuously and stably in high-temperature and high-viscosity silicone melts to ensure the smooth operation of the production line.

In summary, the melt pump plays a key role in silicone extrusion, and is an indispensable equipment to improve production efficiency and product quality.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755