- Position:

- Batte Melt pump > NEWS >

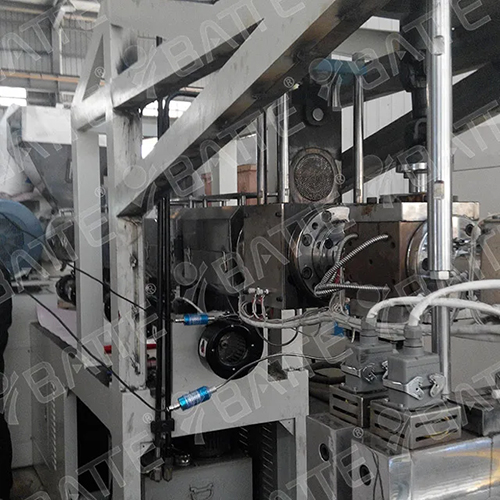

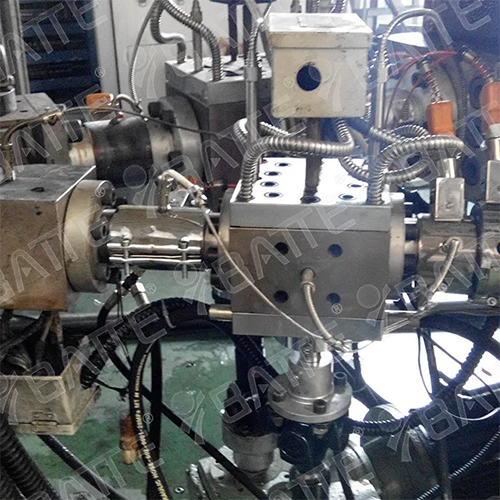

Plastic Cosmetic Tube Extruder Making Machine melt pump

The extrusion melt pump on the plastic cosmetic bottle production line is one of the important equipment in the cosmetic packaging industry. With the continuous development of the cosmetics market and the changing demands of consumers, the shape, material, and packaging methods of cosmetics bottles are also constantly being updated. In order to meet market demand, the design and manufacturing of extrusion melt pumps for plastic cosmetic bottle production lines are constantly being upgraded and improved.

Firstly, let's understand the basic principle and function of the extrusion melt pump in the plastic cosmetic bottle production line. Extrusion melt pump is a device that feeds molten plastic into a mold through an extruder for molding. In the plastic cosmetic bottle production line, the function of the extrusion melt pump is to transport the molten plastic raw material into the molding mold, and shape the molten plastic into the desired shape of the bottle through the shape and pressure of the mold. The performance of the extrusion melt pump directly affects the molding quality and production efficiency of the bottle.

In the design and manufacturing process of extrusion melt pumps, multiple factors need to be considered. Firstly, the material and structural design of the pump need to be able to withstand high temperature and high pressure working environments, and have sufficient wear and corrosion resistance. Secondly, the speed and flow control of the pump need to be adjusted according to the speed and output of the production line to ensure the quality of bottle molding and production efficiency. In addition, it is necessary to consider the maintenance and upkeep of the pump to ensure its long-term stable operation and extend its service life.

With the continuous progress of technology and changes in the market, the extrusion melt pump of plastic cosmetic bottle production line is also constantly upgrading and improving. For example, using advanced control systems and sensor technology to achieve precise control and automated operation of pumps; Adopting new wear-resistant materials and coating technology to improve the wear and corrosion resistance of the pump; Optimize the structural design of the pump, improve the flow and pressure stability of the pump, etc.

In addition to the design and manufacturing of the extrusion melt pump, other aspects of the plastic cosmetic bottle production line also require careful design and control. For example, the selection and processing of raw materials, the design and manufacturing of forming molds, the degree of automation and control accuracy of production lines all have an impact on the quality and production efficiency of bottle forming.

In summary, the extrusion melt pump on the plastic cosmetic bottle production line is one of the important equipment in the cosmetic packaging industry, and its performance directly affects the molding quality and production efficiency of the bottles. With the continuous progress of technology and changes in the market, we need to constantly upgrade and improve the design and manufacturing of extrusion melt pumps to meet market demand and improve production efficiency. At the same time, we also need to pay attention to other aspects of the production line, achieve automation and intelligence of the entire production process, improve production efficiency and product quality, and provide consumers with a better cosmetic packaging experience.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755