- Position:

- Batte Melt pump > NEWS >

What are the characteristics of high-temperature plastic sheet extrusion melt pumps?

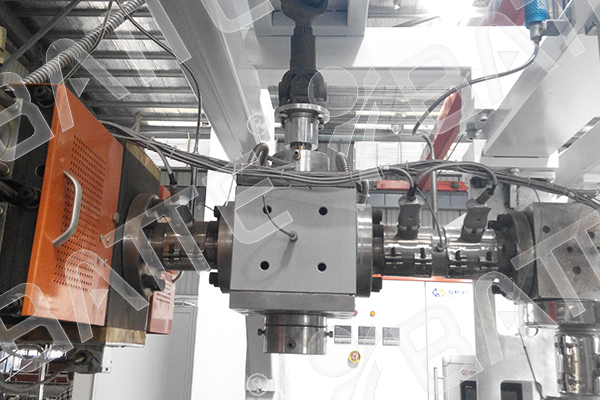

The pump melt gear pump for plastic extruder is suitable for the transportation, pressurization, and metering of high-temperature and high viscosity polymer melts. It is generally installed between the outlet of the extruder and the head, and is widely used in polymer extrusion molding such as granulation, film, pipe, plate, and sheet materials. It can also be installed in pipelines to transport high viscosity pure materials.

pump melt gear pump for plastic extruder

Characteristics of plastic sheet extrusion melt pump:

1. Minimal pressure and flow pulsation can achieve linear output of flow, suitable for precision extrusion systems.

2. Adopting different structures and material configurations for different working conditions can better meet the personalized needs of users.

3. It can be applied to high temperature (350 ℃), high pressure (40MPa), and high viscosity (40000 Pass) working conditions.

4. Precision structure, high precision, and long service life.

melt pump for extrusion

The high temperature melt pump is made of high-temperature alloy steel and powder alloy steel. After a series of hot processing and surface treatment such as high-temperature quenching, tempering, tempering, nitriding, carburizing, carbonitriding, and polishing, the product has characteristics such as high temperature resistance, high pressure, high wear resistance, and corrosion resistance. The product hardness can reach 62-68HRC, which can greatly meet the requirements of customers for different working conditions.

plastic sheet extrusion melt pump

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755