- Position:

- Batte Melt pump > NEWS >

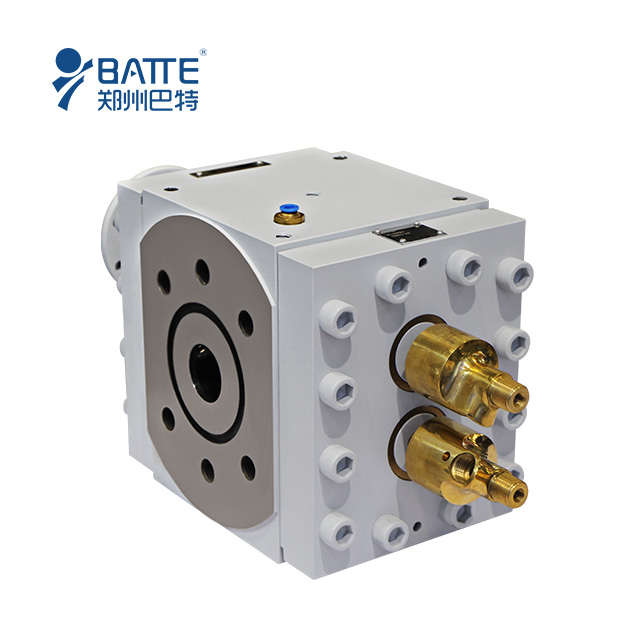

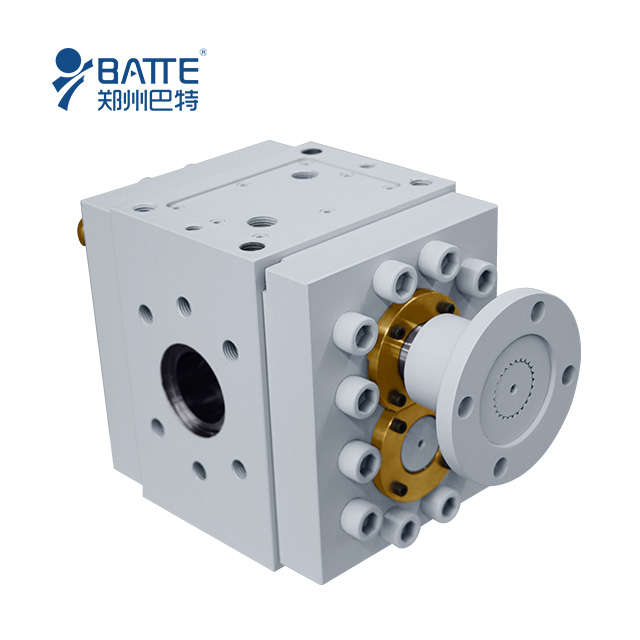

Melt gear pumps for rubber extrusion systems

Introduction to rubber extrusion melt pump:

The optimized melt flow channel design of the rubber melt gear pump eliminates dead corners in the flow channel, avoids polymer residue, and improves the quality of the product. The rubber melt gear pump has a built-in cooling channel for more precise and fast temperature control.

Technical parameters of Melt gear pumps for rubber extrusion systems

Mooney viscosity: ≤ 120

Working temperature: ≤ 130 ℃

Cleaning temperature: ≤ 350 ℃

Outlet pressure: ≤ 70MPa

Pressure difference: up to 50MPa

Specification/flow range: 50CC -12000CC

The installation of the melt pump in the extrusion system can significantly improve the stability of the die head pressure, thereby improving the quality of the products in process; At the same time, it can also increase extrusion volume, increase production, and save costs for users. Improved gear parameter design: More precise displacement design, making the output pressure more stable and suitable for precision extrusion conditions. Our company's specialized melt pump for rubber and elastomers has an optional transfer capacity of 5cc/r~8000cc/r.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755