- Position:

- Batte Melt pump > NEWS >

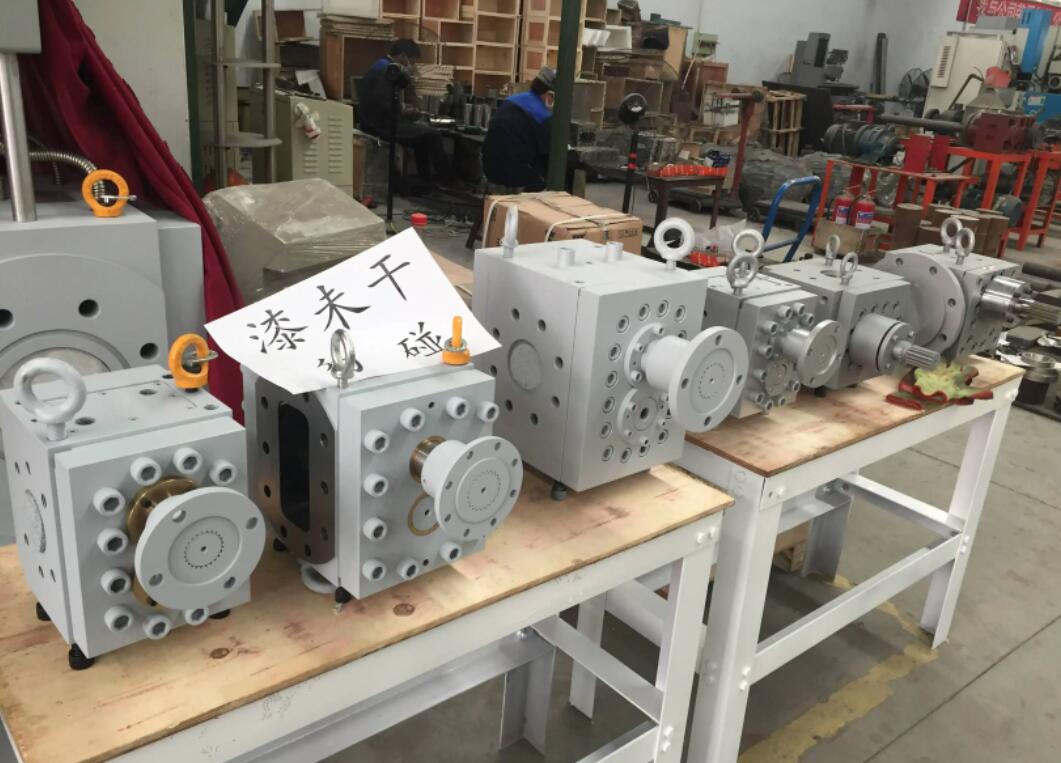

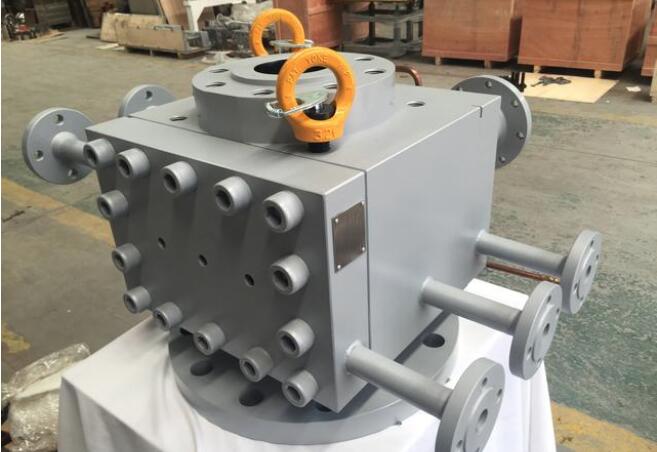

Gear pumps for polymer applications

Polymer melt pumps, when used in conjunction with screw extruders, can improve extrusion output and quality, reduce energy consumption, and play a role in precision extrusion molding that cannot be replaced by other processing methods. At present, it can process materials covering most polymer materials, such as PE, PC, PP, PVC, PET, polysulfone, polyester, fluoropolymers, thermoplastic elastomers and rubber, etc. It has become a hot spot for the development of modern plastic molding and processing technology and equipment.

1, can achieve stable extrusion, improve the accuracy of the extrudate size, reduce the scrap rate

Because in the extrusion process, the uneven amount of material feeding, the different proportion of recycled material adulteration, barrel and head temperature fluctuations, screw speed pulsation and other phenomena is difficult to avoid, the installation of gear pumps can significantly reduce the upstream fluctuations, play a role in pressure stabilization. This is because: ① melt gear pump gap is very small, the material flow resistance in the gap, leakage flow is very small, the amount of fluctuations in the leakage flow rate caused by changes in differential pressure has little effect on the pumping volume; ② melt pressure fluctuations are related to its own frequency of change. If the inlet pressure fluctuations do not have enough time to change from one state to another, then the fluctuations generated during engagement will not directly affect the outlet pressure fluctuations.

2、Increase output, reduce energy consumption and increase machine life

Due to the installation of polymer melt gear pump on the extruder, the pressure building function of the extruder is transferred to the gear pump to complete, the extruder can work at low pressure and low temperature, the pressure flow is greatly reduced and the output is increased. Another advantage is that the temperature rise of the material decreases, which is beneficial to the improvement of the strength, impact resistance, heat resistance and other physical properties of the extruded products, providing the possibility to increase the screw speed and increase the output.

3, with linear output characteristics, easy to coordinate the work of upstream and downstream equipment

Since the gear pumps for polymer applications has less leakage flow, the conveying capacity of the pump is basically linear with the rotational speed, and the flow rate of the polymer melt pump can be known exactly after the rotational speed is changed, so that the working speed of the upstream and downstream equipment can be determined and the main and auxiliary machines can work in coordination to ensure that the products are formed in a stable state.

4、Strong adaptability and wide range of application

Because of the hard working characteristics of melt gear pump, it is highly adaptable to different material types, head resistance and operating process conditions, so it has a wide range of applications. Most of the polymer products can be extruded by extrusion melt gear pump, especially in the field of bi-directional stretch film, non-woven fabric, coating, wire and cable, multi-layer composite sheet, film, chemical fiber and other precision extrusion molding, melt gear pump has been widely used.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755