- Position:

- Batte Melt pump > NEWS >

Operating efficiency of melt pump and D-type bearing

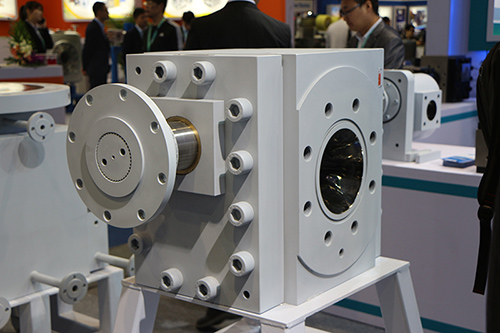

There is a small amount of melt loss in the melt pump, which makes the operating efficiency of the pump unable to reach 100%, because these melts are used to lubricate both sides of the bearing and gear, and the pump body is never fit without clearance, so the melt cannot be discharged from the outlet 100%, so a small amount of melt loss is inevitable. However, the melt pump can still operate well, and for most extruded melts, the efficiency can still reach 93% - 98%. The rotation speed of a melt pump is actually limited, which mainly depends on the conveyed melt. If oil is conveyed, the pump can rotate at a high speed. However, when the melt is a high viscosity polymer melt, the rotation speed of the pump will be greatly limited.

The "d" type bearing of the melt pump combines the forced lubrication mechanism to make the polymer melt pass through the bearing surface and return to the inlet side of the pump to ensure the effective lubrication of the rotating shaft and reduce the possibility of polymer melt retention and degradation. The precision machined pump body can make the "d" type bearing and the gear shaft fit accurately to ensure that the gear shaft is not eccentric to prevent gear wear.

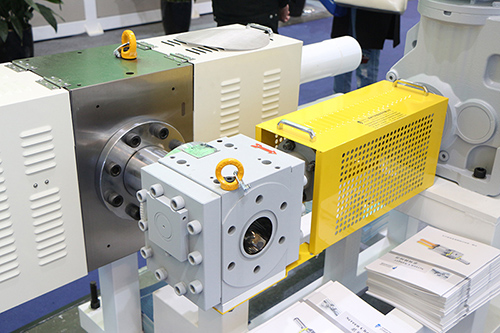

Zhengzhou Batte is a professional melt gear pump manufacturer in China, which can provide melt gear pump products of different specifications and models to meet the production requirements of different working conditions; Drive system, control system and screen changer can also be selected according to user requirements.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755