- Position:

- Batte Melt pump > NEWS >

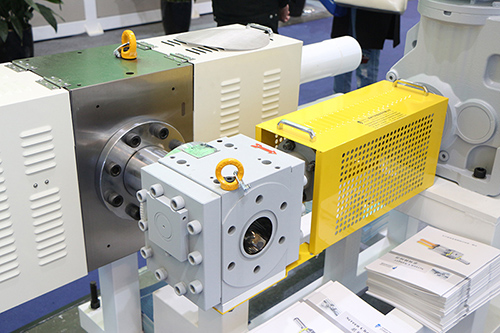

What are the disadvantages of the mechanical seal of melt pump?

In order to keep the melt pump in a good running state, reduce the times of shutdown and maintenance, and then reduce the times of pump lifting and lowering load, the technical transformation of the mechanical seal is carried out from prolonging the service life of the mechanical seal. The welded bellows mechanical seal is adopted to reduce the leakage point of the mechanical seal and improve the service life of the mechanical seal. The mechanical seal structure used in the melt pump has the following deficiencies after a period of use:

1. The stress of O-ring or packing is released after long-term use, which reduces the clamping force on the shaft sleeve and causes leakage.

2. For mechanical seals working under high temperature (above 250 ℃), high requirements are put forward for the material selection of O-rings or fillers, which is easy to cause aging and shorten the service life of mechanical seals.

3. For the mechanical seal working with sealing fluid, the sealing fluid cannot operate in time at the initial stage of installation, and the pump body temperature of the melt pump is high, resulting in the rapid expansion of the graphite packing ring of the mechanical seal. When the sealing fluid operates, the temperature of the mechanical seal cavity decreases and the graphite ring shrinks, while the preload of the graphite ring gland bolt is not enough to compensate for the shrinkage deformation of the graphite ring, resulting in the leakage of the mechanical seal.

4. The mechanical seal of this structure puts forward high requirements for the technical level of the installer. It is not easy to locate accurately during installation, which is easy to cause the deflection of the moving ring and lead to the leakage of the mechanical seal.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755