- Position:

- Batte Melt pump > NEWS >

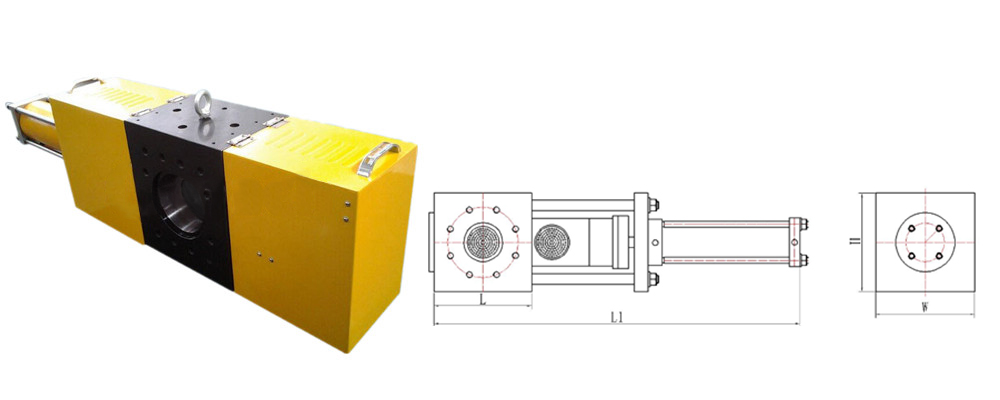

Hydraulic Screen Changer

Hydraulic Screen Changer also called HSC, and allows for filtration of most polymers with minimum disruption during a screen change. The following features, benefits, and applications are details for you.

Hydraulic Screen Changer Features:

Patented pressure activated seal

Seal design eliminates hang-up areas

All seal parts - 4140 heat treated steel

Breaker plate open area largest in the industry

Rugged, tight-fitting, tamper proof guards

Industry standard interface connections

Slide Plate heater wires flex away from poly

One or three zones of temperature control

Process temperatures from 100° F - 700° F

Hydraulic Screen Changer Benefits:

Patented seal eliminates degradation and gels

Seals never need replacing - no maintenance

Many parts interchangeable with other makes

Guards are truly safe protecting operator from mechanical and burn injury

Slide Plate heater design means less maintenance

Design meets most applications without costly options

Improvements equate to lower installed and operating costs

Hydraulic Screen Changer Applications:

Sheet

Coating

Pipe and profile

Compounding

Wire and cable

Tubing

Lab lines

EVA, hot melt adhesive and PSA

Pelletizing (strands and underwater)

Blown film and cast film

Degradable materials

The Hydraulic Screen Changer allows for filtration of most polymers with minimum disruption during a screen change. Batte Hydraulic Screen Changers feature a patented pressure activated seal that not only seals to 10,000 psi, it eliminates degradation and gels caused in other slide plate type screen changers. Hydraulic Screen Changers are designed to withstand extreme temperatures and filter highly sensitive compounds. Unit can be supplied with either one or three heat zones.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755