- Position:

- Batte Melt pump > PRODUCT > Gear Pump for Reactor >

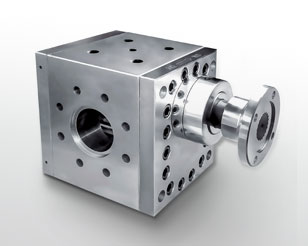

Melt Pumps: extrusion line synchronization Made Easy

You can eliminate extruder surge and screw beat at the die by installing gear pumps between your extruder and die. Our fusion pumps are extremely effective in the construction of the pressure and metering of the polymer chain at a flow rate and a very consistent pressure.

Melt pumps come in a variety of types and sizes to fit the needs of your extrusion, compounding or polymer production process.

Standard extrusion pumps for unloading pressure to 5000 psi (345 bar).

Extrusion pumps high pressure: pressure up to 10,000 psi (690 bar).

High precision extrusion pumps: performance Virtually impetus for specialty film the most demanding and profile extrusion processes.

Polymer composition pumps: Designed for maximum quality in granulation lines.

Place of Origin: Henan, China (Mainland)

Brand Name: BATTE

Model Number: ZB_B,ZB-C,ZB-D,ZB-E,ZB-F,ZB-G,ZB-H,ZB-K,ZB-R

Usage: Plastic, Rubber Pump and Fiber

Power: Electric or Oil

Fuel: No Need

Pressure: High Pressure

Application: transportation, pressurization or the metering of polymer

Scope of Application: Almost all kinds of polymers

Viscosity: Up to 40000Pas

Gear Tooth: Straight (Optional),Helical gear pump(Optional),Herringbone gear pump(Optional)

Sealing Method: Mechanical Sealing (Optional)

Heating Method: Stainless Steel Heating Rod

Packaging Details: Items are usually wrapped with foam plastics, and then packed in wooden case.

Delivery Detail: 5-6 weeks after receiving the 30% prepayment from the customer

Email: info@battemachinery.com

Whatsapp: +86 158 38331071